WHY AWEX?

EFFICIENCY HAS A NAME

AWEX carton-strippers are highly engineered and continually improved devices for the cardboard industry. The high quality standard is ensured, among other things, by the consistent development and production "Made in Germany". Experience gained from over 40 years of production and further development ensures maximum reliability and productivity.

40 Years anniversary

We will celebrate our 40th company anniversary in 2024 and would like to take this opportunity to thank all of our customers worldwide for their trust. Just in time for the anniversary, we are pleased to be able to introduce you to two new models of our successful AWEX carton-strippers. The AWEX-T3 and the AWEX-T4 carton-strippers are now available in two versions each.

.

OPTIMIZE THE STRIPPING PROCESS

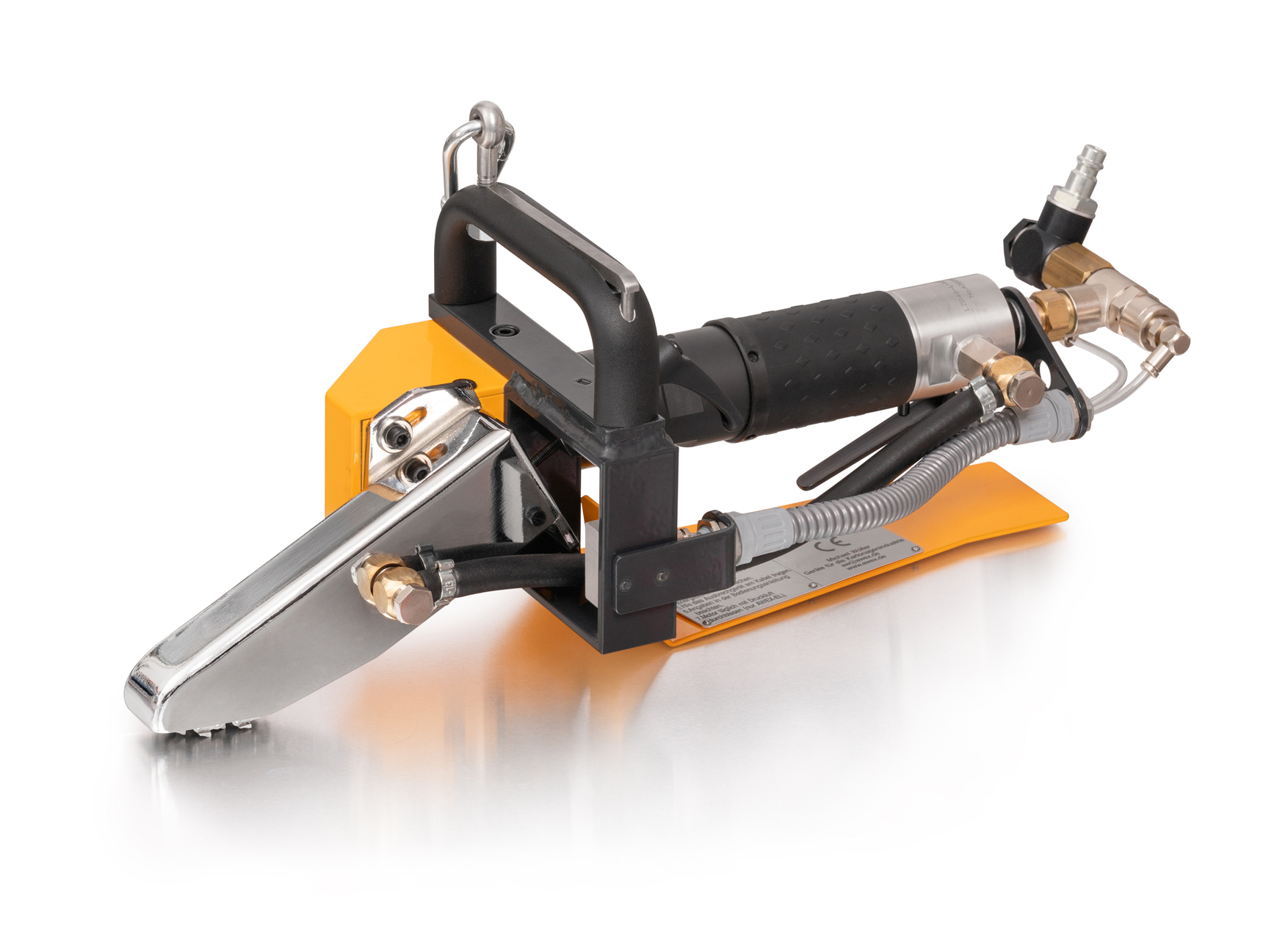

With our AWEX carton-strippers you can mechanically remove the external punching waste from cardboard, microwave, corrugated cardboard, plastic corrugated cardboard, laminated and other formats.

Optimize the stripping process in your further processing. Save yourself the time-consuming, costly and strenuous breaking out by hand.

Our AWEX carton-stripper are a purchase that will pay for itself in a very short time and will save time and reduce high labor costs in the future.

By using our AWEX carton-strippers, you can remove the external punching waste quickly, safely and effortlessly. In addition, when the stacks are removed, they remain layered exactly as they left the punch.

Designed according to the requirements of our customers, our AWEX carton-strippers have proven themselves worldwide in the printing and cardboard packaging industry for over 40 years.

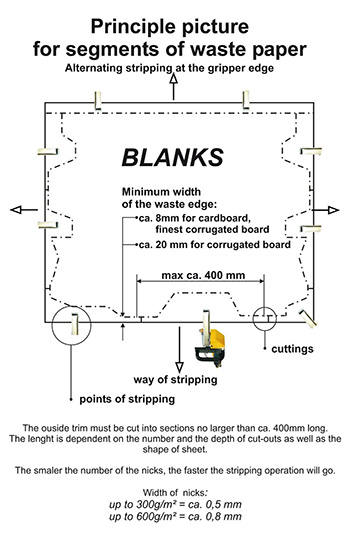

Subdivide the waste edge in a way that the chain can operate at the widest part of the waste edge.

Furthermore, the smaller the number of nicks (to heed at new forms), the faster the stripping operation will go.

The AWEX carton-stripper removes the trim section by section at high speed. A section of the stack of 250 sheets high can be removed in one second for instance.

This performance results in a substantial lowering of manual stripping cost.

The Original

AWEX Carton-Stripper

Trust the Original | Since 1984

AWEX Sustainability

By using a basic platform, we can assemble our different motor types, with the always identical gearbox platform, into the different pneumatic AWEX types. This measure reduces stockkeeping, ensures a secure supply of spare parts for decades, ensures consistent high quality and finally reduces purchase prices for our customers.

The fact is that we are still receiving devices for repair that are sometimes 30 years old and are still in use. Here, too, we can help in most cases, even if we sometimes have to dig deep into the spare parts box.

We are also very keen to support the regional economy. The few purchased components are all produced in the European Union.The majority of the AWEX components such as all laser, milling and turning parts as well as welding, hardening, chrome and painting work are manufactured and carried out exclusively by us and highly qualified companies from the region.This is more expensive than having production carried out abroad, but in the end our demands for quality, trust, job retention and community entrepreneurship prevail.

That's why our AWEX carton-stripper will continue to bear the “Made In Germany” seal in the future and we are very proud of that.